The Challenge

The premium German automotive OEM wanted to combine the data they had in different systems to create a holistic production reporting that will give a complete overview of their production.

Background of the Project

The complex production IT landscape consists of several specialized systems for the different processes like quality control, production monitoring, track and trace, and other functions. The production reporting consisted of several reports where information was in parts loosely connected due to the data silos.

These connections were mostly based on the experience of individual senior engineers.

The client wanted to improve the processes quality by integrating the data and breaking the data silos.

The Process

The project started with the analysis of the reports and interfaces used by the engineers then went on to the analysis of data structures of the different systems. Identifying the flow of data and knowledge generation processes, basically where was information collected from and how the data connected.

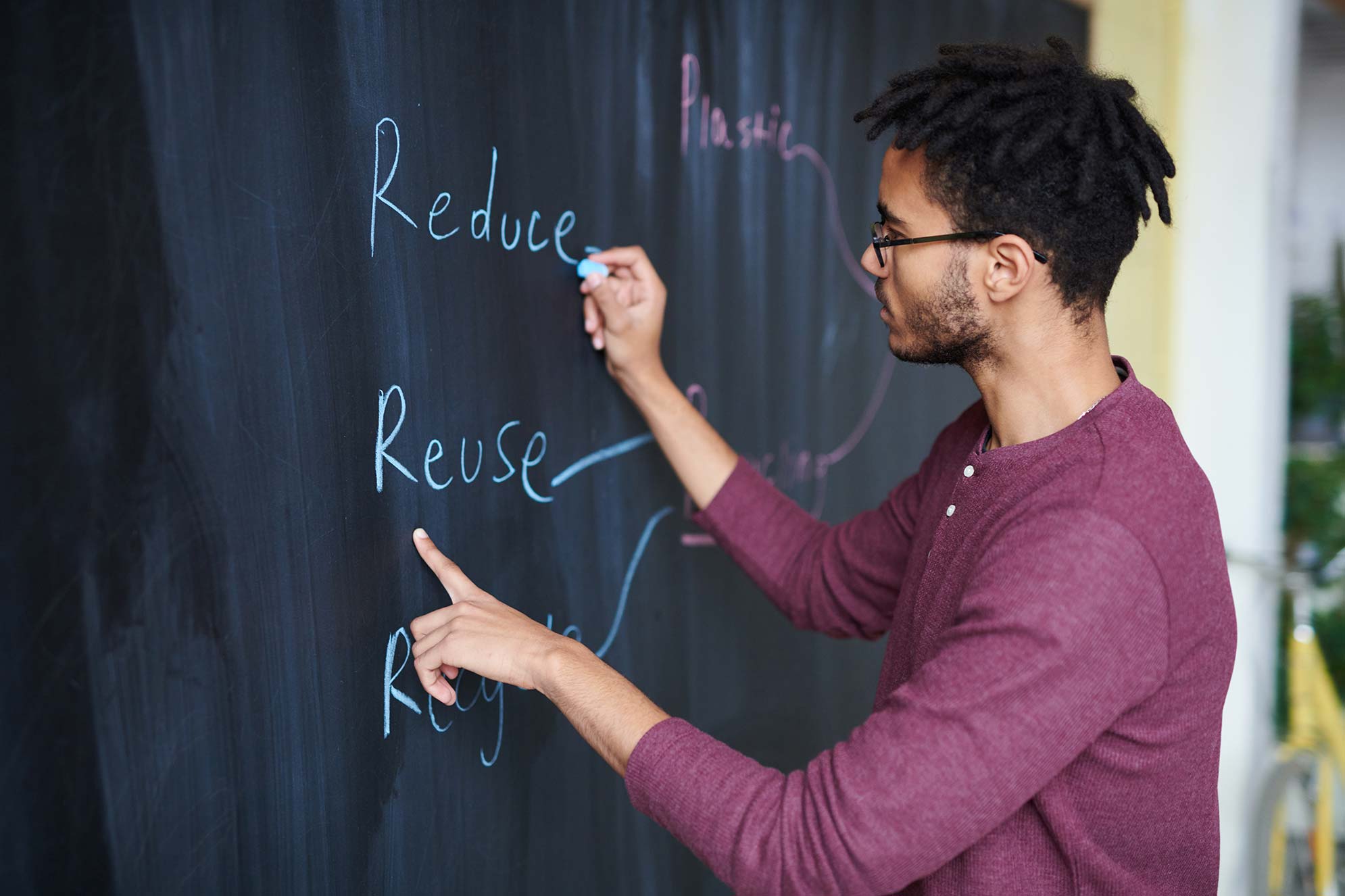

Iterative and collaborative development lead to faster results

Once the data structure was clarified, the development of the interfaces and dashboard was started in an agile project, where results were presented and discussed regularly with the domain experts.

This helped ensure that both the client and development team were verifying the product and reacting fast to changes.

Conclusion

Bringing together domain knowledge and information technology expertise is not easy in a complicated setting like a modern production plant with all the different processes, systems and data. But it’s worthwhile, as it helps eliminate waste and enables a much higher degree of effectiveness.

Improved error handling and lower down times.

The dashboard pulled all the relevant data from the multiple systems to create a complete picture of the production, helping to analyze performance as well as issues and gain insights.

This helped improved overall equipment effectiveness.

This helped operators as well as management better understand the factors that influenced their production and what an impact they would have across the whole production.