Background of the Project

As a premium automotive OEM, our client was using different specialized Manufacturing Execution Systems (MES) across its various locations worldwide. However, these disparate systems were inefficient, costly, and lacked integration, leading to data silos and operational inefficiencies. The client needed to standardize its MES systems and replace all niche and specialized systems with a modern, enterprise-wide system to optimize manufacturing operations.

The Challenge

The client’s legacy MES systems were heavily modified, lacked documentation, and were specialized for different areas such as body shop, paint shop, or press shop. To replace these systems, the new MES had to be adaptable to the client’s specific needs and integrate with existing interfaces, databases, reporting, and management dashboards for quality, production monitoring, and alerting systems. The project was expected to take two years to complete, and any downtime or delays would negatively impact production and revenue.

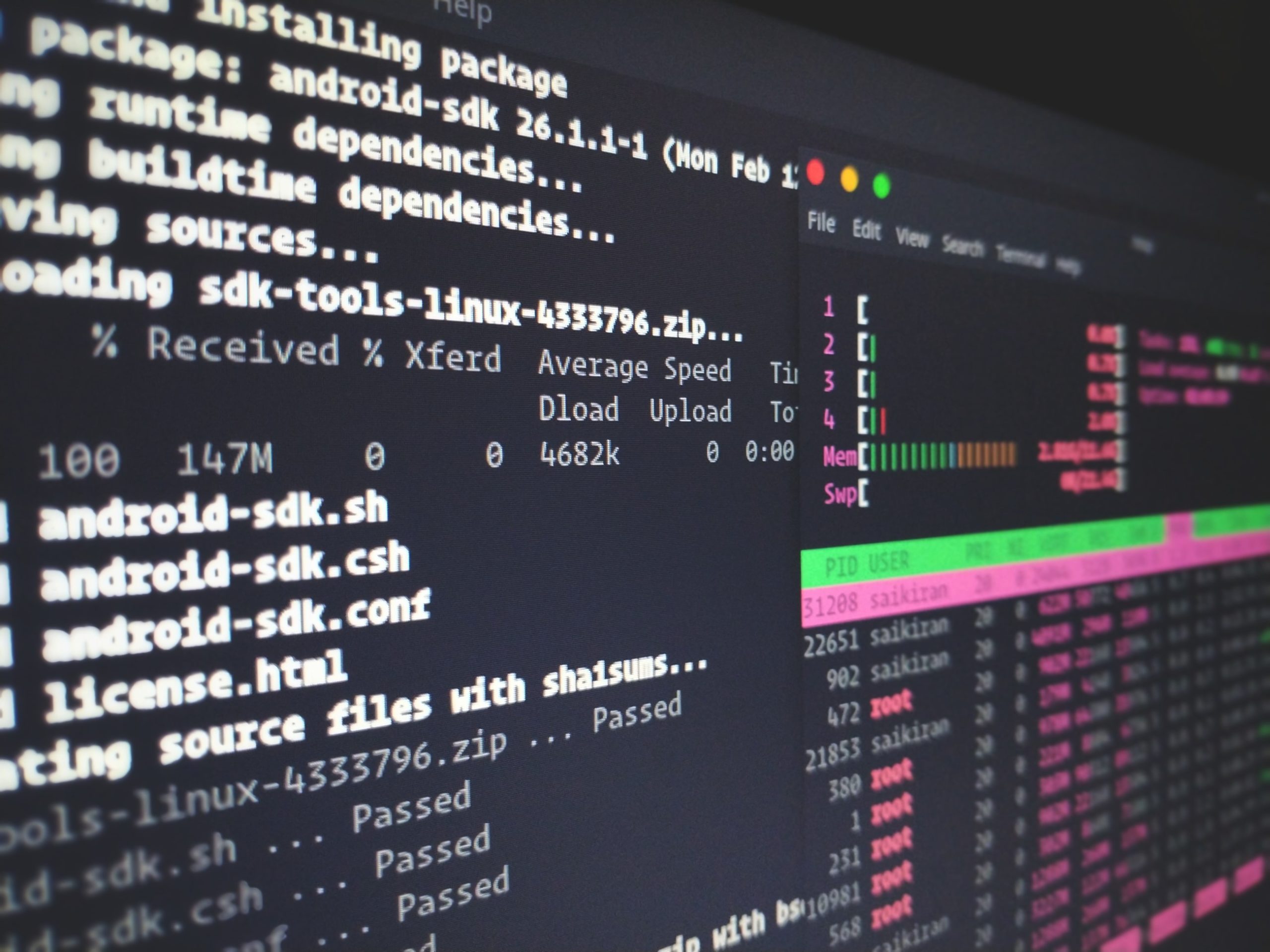

The Process

Our team of experts analyzed and adapted various specialized legacy MES systems to the new modern global standard. We developed interfaces for machine communication, databases, reporting, ERP and management dashboards. The new MES was adaptable to the client’s specific needs and integrated with existing systems. We provided extensive training to the client’s employees to ensure smooth adoption of the new system.

Results

After the two-year project, the client successfully replaced all niche and specialized MES systems with the new enterprise-wide system. The new MES improved data integration and accessibility, leading to better operational efficiencies, reduced downtime, and increased productivity. The new system also provided real-time visibility into production data, enabling faster decision-making and better quality control. The client was able to save on costs by eliminating the need for multiple systems and reducing maintenance and support costs. Overall, the new MES system helped the client achieve its goal of standardizing manufacturing operations and improving productivity across all locations worldwide.

Conclusion

Replacing legacy MES systems can be a complex and challenging process, especially when dealing with specialized systems across multiple locations. However, with the right expertise and approach, it is possible to standardize manufacturing operations and improve productivity. Our team helped the client successfully replace all niche and specialized MES systems with a modern, enterprise-wide system that improved data integration and accessibility, leading to better operational efficiencies, reduced downtime, and increased productivity.